|

The `Thick skins` versus the `Thin skins`

The Gato Class Fleet Type submarine was the class of submarine being produced by shipyards for the United States Navy when the Japanese attacked Pearl Harbor on 7 December 1941...plunging the United States into the Second World War as an active participant. The Gato Class Fleet Type submarine was the class of submarine being produced by shipyards for the United States Navy when the Japanese attacked Pearl Harbor on 7 December 1941...plunging the United States into the Second World War as an active participant.

By the time the Gato Class was designed, the simplification and weight-saving programs mounted by the Bureau of Ships and the Portsmouth Navy Yard had built up a substantial margin of surplus available tonnage for use in future submarine construction. This had to be offset by the addition of scarce and expensive lead ballast...that was used to keep the displacement of the boats unchanged but contributed nothing but dead weight to the submarines. To designers, the ideal solution to this problem was to convert the lead weight into steel...where it would do the most good by providing a heavier and deeper-diving pressure hull. At the same time the structural experts in the Bureau of Ships were considering changing the basic material for submarine hulls from the familiar mild steel to the stronger high tensile steel (HTS). Calculations demonstrated that the hull plating could be increased from the approximately 9/16-inch (27.5 pounds per square foot) material used in the Gato Class, and preceding classes, to 35-pound plate about 7/8-inch thick. This would make the hull capable of withstanding submergence to 925 feet without collapsing, assuming the use of the new HTS. Even if mild steel had to be used, in case a shortage of the other should develop, the collapse depth could still be increased to 650 feet. The extra strength would be of great advantage to submarines in a combat situation, but in order to be safe, the designers proposed that the operating depth be set officially at 450 feet.

The essential features of the new design were worked out just before the Japanese attack on Pearl Harbor, in time to be presented to the Chief of the Bureau of Ships. However, the Chief felt that the proposed depth increase, from the 300 feet operating depth of the Gato Class, was too radical a jump, and, that, although the hull might be strong enough, it would also be necessary to prove that vital machinery components, such as the trim and drain pumps, which were utilized to expel water from the submarine, could perform satisfactorily at the deeper depth. Those pumps were based on a German design that had remained essentially unchanged since the end of World War I, and tests showed that the pumps could not develop the required discharge pressure. As a result, the operating depth for the new hull was formally set for 400 feet. However, the Bureau specified the test requirements for everything in the boat at 1½ times the pressure existing at 450 feet, thus providing a substantial extra margin of performance...and safety.

Except for the heavier hull structure, the new Balao class design, named for the lead submarine designated to be built with the heavier hull plating, was almost identical in equipment, layout, and appearance to the Gato type and was first phased into the Portsmouth Navy Yard construction schedule without a break in the rate of production. Among submariners, the new boats soon became known as `thick skins` and the older ones as `thin skins`, and there was considerable argument over the behavior to beexpected of the new steel under depth-charging. Some felt that the heavierhulls might rupture where the thinner and more flexible plates would only dimple, and were perfectly content to stay with the older boats even though they obviously could not dive as deep. Their fears proved to be unwarranted.The Bureau`s conservative approach to increasing the operating depth for the heavy-hull boats turned out to be wise, for an unanticipated reason. Because of the huge wartime demands for steel and the difficulty of obtaining certain critical alloy elements, the mills were having problems meeting all requirements. Therefore, without the prior knowledge of the submarine designers, the government specifications for HTS were relaxed from chrome-vanadium steel with yield strength of 50,000 pounds per square inch, to a titanium manganese alloy with 45,000 pounds per square inch yield strength.

Although this was considerably stronger than the mild steel previously used in submarines, it was less than the submarine hull designers had planned on. But the extra margin of safety designed into the boats was sufficient to absorb the difference. Since it was obviously impossible to test every square foot of plating going into a submarine, the design margin was also intended to assure the strength and integrity of the hull, in case some substandard steel got by the inspection process.

Specifications, Gato class:

The lead boat of the class was laid down on October 5, 1940, at Electric Boat Co., Groton, CT.; launched, August 21, 1941; commissioned USS Gato (SS-212), December 31, 1941;

Displacement (srf/sub tons): 1,526/2,424

Dimensions (L*B*D feet): 311`9*27`3*15`3

Propulsion: diesel-electric,4*GM-Winton V-16, or 4*Fairbanks-Morse 9 or 10-cylinder opposed-piston diesel/generator sets, 5,400hp, 4* Elliot Motor Co. electric main motors with 2,740hp, reduction gear, two 126-cell main storage batteries, two propellers

Speed (srf/sub knots): 20.25/8.75

Range (srf/sub n/miles@knots): 11,000@10/100@2

Diving depth (feet): 300

Complement: 6 officers 54 enlisted

Torpedo: 6*21" bow torpedo tubes, 4*21" stern torpedo tubes, total of 24 torpedoes

Mines: none

Armament: 1*3"/50 main deck gun, 2*0.5 cal. AA machine guns, 2*0.30 cal. machine guns

Construction

77 boats ordered between 1941 and 1943.

Back to History Index

|

United States |

|

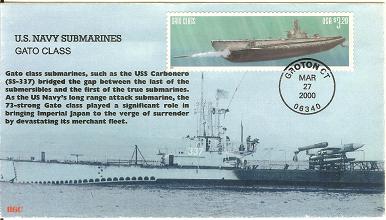

US Navy Submarines Gato Class, Groton CT, 27 March, 2000 |

|

Guyana |

1995 |

USS Gato class submarine |

|

United States |

2000 |

Gato class (USS Gato SS-212) |

|